VIMATHERM PHE is a dismantlable Gasketed Plate and Frame Heat Exchange,

specially designed to guarantee the best operation and the longest lifetime for each of its components.

VIMATHERM

heat exchanger plates are pressed in one single stroke by large tonnage hydraulic presses.

This enables compliance to extremely tight tolerance, allowing large

plate packs to be perfectly aligned in when assembled.

The profile of the plates has been specially designed to generate high

turbulence, which guarantees high heat transfer rates and a resistance

to fouling higher than average.

Technology

VIMATHERM technologies

ensure one of the longest lifetimes for plates and gaskets and one

of the lowest life-cycle costs on the market, due to:

-

The gap between plates and the pressing depth are calculated to reach

the best compromise between thermal performances and fouling time.

-

The half-cylindrical gaskets technology allows the heat

exchanger to bear several operations of assembly and dismantling, and ensures the

original gaskets to last longer and limits the frequency at which these

parts should be replaced.

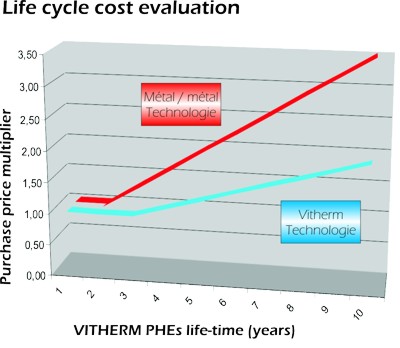

Why choose VIMATHERM heat exchangers

Most plate heat exchangers on the market use metal against

metal tightening technology. This technology compresses

definitively the gasket in its groove to its lowest tightening size, which means it

has to be changed as soon as the exchanger is dismantled for the first

times, in most cases.

VIMATHERM

technology allows all the exchangers of the range to have an average tightening size ex

works, which allows to adapt progressively the retightening of the

equipment after each dismantling, until it reaches its lowest

tightening size (contact metal/metal).

With this technique, plates are not tighten metal

against metal at the first assembly but only after several dismantleling operations. This

process protects the gasket and allows its re-use for several

maintenance and cleaning cycles.

This technology was achieved to fulfil industrial requirements, and allows

VIMATHERM heat exchangers to have one of the lowest life

cycle costs on the market (purchase price + operational costs).